Automations

Mancin Automazioni Srl is a structured company for the realization of industrial automation projects. To finalize the activity, a first phase of analysis of customer data is always carried out, followed by the realization of the hardware from the project (the wiring diagrams) to the electrical panel, using the most suitable electronic and electromechanical components for the application. 'installation. of the edge of the machine.

We also create system management and control software.

We offer modular solutions for every type of company, from small to large companies, creating applications with advanced technological innovations, using PC, numerical controls, PLC, axis boards, brushless drives, inverters, analog / digital servo valves, etc. of the major manufacturers (Siemens, Bosch-Rexroth, Rockwell, Baldor, etc ...).

The plants are located in their production sites, often abroad, and that is why Mancin Automazioni, already in the design phase, puts in place functional strategies able to achieve an efficient Tele-Assistance with the purpose of monitoring, verifying and possibly modify every part of the system's functional logic in maximum security through Internet-Intranet and / or analogue modem, ISDN, GSM, UMTS etc …

Scada applications

For over 20 years Mancin Automazioni has implemented supervision and control software for machines and plants, specializing its products in production management solutions, data acquisition for production reports, warehouse management, data collection, maintenance, traceability and traceability of products, etc ...

Depending on the application and needs of our customers, we realize the projects using the commercial software SCMI HMI and / or by directly writing native code in C / C ++, VB, Java and interfacing it to the automation with DLL and / or OPC Server for make all information deriving from the system in question accessible to the operator.

Our projects can therefore be applied on the operator panels of various brands and / or industrial and non-industrial PC, creating direct interfaces for Windows operating systems and / or creating Web pages for direct viewing on browsers without the need to install API. Therefore, our customers can also use alternative hardware and operating systems for Windows.

Switchboards

Switchboards are a matter of experience, every single product made increases our experience.

The electrical panels of the plants are made at the Mancin Automazioni offices. In an increasingly demanding market, we are able to compete both in terms of quality and production, thanks to highly specialized personnel and our equipment. An important component of our success is the ability to test and test the operation of the plant at our premises, using techniques and methodologies designed by us that simulate the system hardware, drastically reducing the time of commissioning with our customers . In fact we are able to reproduce the cycle of automatic application bringing the system (Hardware / Software) in critical situations to simulate any type of reaction, making the project immune to unexpected behavior.

We take care of the design, production and certification of all electrical panels, wiring and functionality control through insulation test and ground conductor, according to the principles and the Directives / CE Standards. We also manufacture and certify electrical panels according to UL and CSA standards for the United States and Canada markets. With these assumptions, our pool laboratory manufactures electrical panels, electrical and control panels, general distribution panels and secondary panels. This type of electrical panel is used differently: management of rotating shelves, snow cannons of various types, solar energy systems, heating systems and so on.

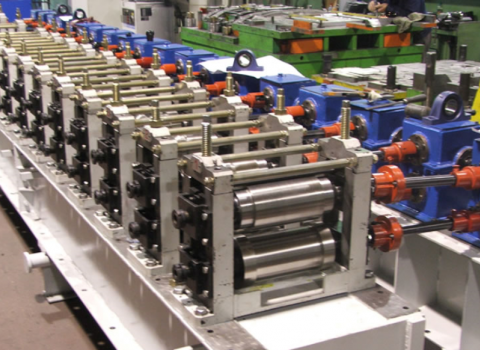

Edge of the machine

Thanks to constant attention to technological innovation, we evaluate, design and produce the most suitable solution for the edge of the machine depending on the characteristics of the system, its position and the needs of the customer. Our strength is the integration of the most advanced technologies with over twenty years of experience in industrial automation.

We can offer on-board automation using traditional methods (direct or toothed wiring of components) or using the most suitable fieldbuses such as ProfiBus, ProfiNet, DeviceNet, CANopen, ASI-Interface or communicating directly via Ethernet with equipment production that Office world for the communication of sensitive data, cable or Wireless solutions.